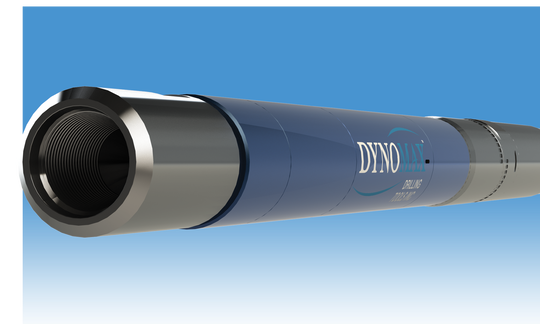

Industry leadersDynomax is a supplier of leading performance drilling products engineered for the oil and gas industry. |

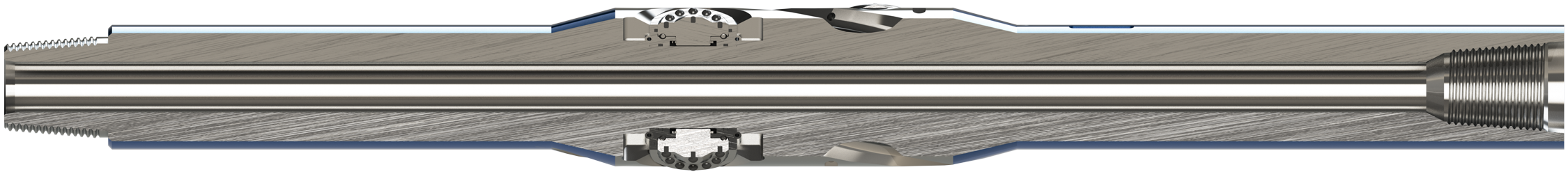

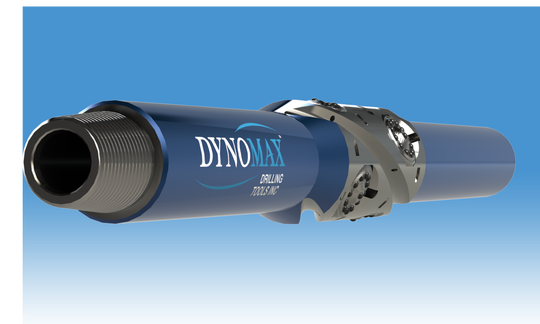

The cutting structure on the slide reamer is designed to maintain 360 degree contact. Cutters rotate independently throughout the movement, reducing rotary torque and drag by up to 20% (when compared to running a drill string without a slide reamer). Dynomax Slide Reamers used for vertical, directional and horizontal holes eliminating drift or deviation in wellbore applications. |

DownloadsDYNOMAX REAMERS E BROCHURE |

Technical Specifications

Benefits

|

Features

Non-Mag Reamer Bodies are now available in certain sizes! |

|

|

Existing customersRegister with us to view your product documents.Register |

Other great products

We offer industry leading products that stand the test of time on the job.